РЕЗОЛЮЦІЯ: Громадського обговорення навчальної програми статевого виховання

ЧОМУ ФОНД ОЛЕНИ ПІНЧУК І МОЗ УКРАЇНИ ПРОПАГУЮТЬ "СЕКСУАЛЬНІ УРОКИ"

ЕКЗИСТЕНЦІЙНО-ПСИХОЛОГІЧНІ ОСНОВИ ПОРУШЕННЯ СТАТЕВОЇ ІДЕНТИЧНОСТІ ПІДЛІТКІВ

Батьківський, громадянський рух в Україні закликає МОН зупинити тотальну сексуалізацію дітей і підлітків

Відкрите звернення Міністру освіти й науки України - Гриневич Лілії Михайлівні

Представництво українського жіноцтва в ООН: низький рівень культури спілкування в соціальних мережах

Гендерна антидискримінаційна експертиза може зробити нас моральними рабами

ЛІВИЙ МАРКСИЗМ У НОВИХ ПІДРУЧНИКАХ ДЛЯ ШКОЛЯРІВ

ВІДКРИТА ЗАЯВА на підтримку позиції Ганни Турчинової та права кожної людини на свободу думки, світогляду та вираження поглядів

- Гідрологія і Гідрометрія

- Господарське право

- Економіка будівництва

- Економіка природокористування

- Економічна теорія

- Земельне право

- Історія України

- Кримінально виконавче право

- Медична радіологія

- Методи аналізу

- Міжнародне приватне право

- Міжнародний маркетинг

- Основи екології

- Предмет Політологія

- Соціальне страхування

- Технічні засоби організації дорожнього руху

- Товарознавство продовольчих товарів

Тлумачний словник

Авто

Автоматизація

Архітектура

Астрономія

Аудит

Біологія

Будівництво

Бухгалтерія

Винахідництво

Виробництво

Військова справа

Генетика

Географія

Геологія

Господарство

Держава

Дім

Екологія

Економетрика

Економіка

Електроніка

Журналістика та ЗМІ

Зв'язок

Іноземні мови

Інформатика

Історія

Комп'ютери

Креслення

Кулінарія

Культура

Лексикологія

Література

Логіка

Маркетинг

Математика

Машинобудування

Медицина

Менеджмент

Метали і Зварювання

Механіка

Мистецтво

Музика

Населення

Освіта

Охорона безпеки життя

Охорона Праці

Педагогіка

Політика

Право

Програмування

Промисловість

Психологія

Радіо

Регилия

Соціологія

Спорт

Стандартизація

Технології

Торгівля

Туризм

Фізика

Фізіологія

Філософія

Фінанси

Хімія

Юриспунденкция

Table 3

| Items Under Study by the TIA and ISO Standards Groups |

Category 6/Class E

|

Category 7/Class E

|

Barring any unforeseen

technical issues, it is likely

that TIA and ISO approved category 7/class F Standards will be available

to the industry in 2001.

When high density is an important consideration for the Campus Distributor (CD), Building Distributor (BD), Floor Distributor (FD), or Consolidation Point (CP), then SFF connector designs that accommodate at least two fibers within the footprint of an IEC 60603-7 connector are recommended. When used, SFF connectors shall be covered by an approved IEC interface Standard.

As part of the ‘568-B.3 Standard, TIA recognizes SFF connector designs that are physically specified to satisfy the requirements of a corresponding TIA Fiber Optic Connector Intermateability Standard (FOCIS) document or IEC Standard. Compliance to a FOCIS or IEC Standard ensures that the mechanical interface is described in sufficient detail to ensure intermateability between different manufacturers of the same SFF connector style. In addition, in conjunction with IEC and ANSI policy, any patents related to a given SFF interface must be fairly licensed to all manufacturers wishing to produce the interface.

| Figure 4 - 568SC Duplex Connector |

|

Engineers developing connecting hardware found that they could easily provide connectivity for two optical fibers in the same amount of space presently occupied by the copper-based 8-position modular (RJ-45) footprint.

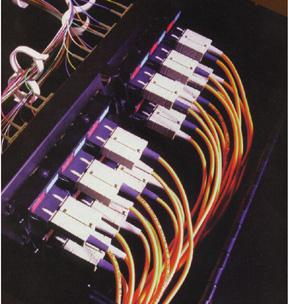

In the previous TIA/EIA-568-A document, only the 568SC duplex adapter and connector (see Figure 4) was recognized for use in the work area for new fiber optic installations. The allowance of the SFF connector offers several potential benefits to the end-user over the 568SC. For example, the 568SC connector, although universally recognized, is larger and does not support the industry trend towards high-density solutions at the equipment interfaces. Engineers developing connecting hardware found that they could easily provide connectivity for two optical fibers in the same amount of space presently occupied by the copper-based 8-position modular (RJ-45) footprint. Since the advent of TIA’s recognition of SFF connectors, fiber optic equipment manufacturers such as Cisco Systems, 3Com, and IBM have already incorporated these interface designs into their products.

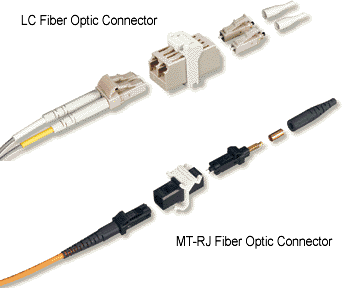

| Figure 5 - MT-RJ and LC Fiber Optic Connectors |

|

To address the industry’s need for SFF fiber optic connecting hardware, The Siemon Company offers a full line of MT-RJ and LC small form factor interconnect products (see Figure 5).

All fibers are eventually terminated, spliced, patched and stored in some sort of Fiber Management Enclosure.

At last look, there were over 100 suppliers of "fiber management" enclosures. How to separate the good from the bad can mean the difference between uninterrupted traffic flow, and system downtime/revenue loss.

Knowing your ABCs is critical in choosing the right enclosure for your network. "A" is for accessibility, being able to access the connectors in a safe way, without disturbing neighboring fibers. "B" is for bend radius control, ensuring that fiber cables maintain proper bend radius when they enter and exit the fiber management enclosure. "C" is for compact design, small enough to maximize the use of valuable rack or wall space, but not too small where accessibility and proper bend radius are sacrificed.

"A" is for Accessibility

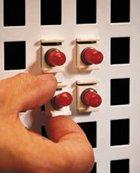

What good is a Fiber Management System (FMS) if you cannot access a specific fiber or connector without disturbing neighboring "active" fibers? Many enclosures of the 1990s still follow the original AT&T LGX footprint and design, utilizing 6-pack adapter plates, held in place by plastic "snap-fasteners" like the nylatch (Figure 1A). Insertion and removal of these 6-packs for additions or cleaning requires two hands, not an easy task when these type of enclosures are fully populated with "active" fiber cables, especially high-density 144 fiber enclosure versions. Inserting two hands to access such a small area (6 in. height x 1 in. width) covered with fiber cables can place undue pressure on these "active" fibers, resulting in high attenuation (Figure 1B).

Figure 1A - "Snap-Fasteners" Figure 1A - "Snap-Fasteners"

| |

Figure 1B - Insert and removal of nylatch-type six-packs requires two hands, placing unwarranted pressure on “active” fiber cables Figure 1B - Insert and removal of nylatch-type six-packs requires two hands, placing unwarranted pressure on “active” fiber cables

|  Figure 2 - The Siemon Company’s Quick-Pack™ six-packs require only one finger to insert or remove Figure 2 - The Siemon Company’s Quick-Pack™ six-packs require only one finger to insert or remove

|

A new patented 6-pack design, trademarked as the Quick-Pack™ , has been recently introduced by The Siemon Company and appears to have solved the accessibility problem inherent in six-pack type enclosures. The Siemon Company’s Quick-Pack™ provides accessibility via the molded-in single-finger latch mechanism for easy insertion/removal (Figure 2 above). The Quick-Pack™ provides necessary access to the connectors for additions and cleaning without disturbing "active" fibers. Now hi-density (144 fibers in a 7 in. high space) can be a reality.

As the nineties emerged, so did the introduction of enclosures with individual (vs. 6-pack) connector/fiber access via the bezel. A bezel is a small plastic part that houses or retains a fiber optic adapter (sleeve, coupling, etc.). Some users prefer access to individual connectors for additions and cleaning, especially where optical splitters are deployed, as the output power of these passive devices can vary greatly if their fiber connector ends are not properly cleaned. Early bezel designs, however, were complicated, requiring 3-4 steps for removal/insertion (Figure 3A), and not very accessible unless your fingers were tiny. Difficulty in removing these types of bezels often resulted in them being dropped into the enclosure, or in fibers stressed from twisting.

Figure 3A - Complicated bezels can require 3-4 steps to insert or remove Figure 3A - Complicated bezels can require 3-4 steps to insert or remove

|  Figure 3B - A new one-step bezel offered by The Siemon Company is much more accessible to the craftperson Figure 3B - A new one-step bezel offered by The Siemon Company is much more accessible to the craftperson

|

The Siemon Company has just introduced a new bezel that requires only one step for insertion or removal, thus eliminating chances of dropping them into the enclosure or stressing "active" fibers. The new patented bezel design requires only one step to mount, merely pressing the bezel into the pre-punched hole in the enclosure until it snaps in to the locked position (Figure 3B).

Accessibility is important in the Splice Enclosure as well. Here is where relatively large diameter trunk or drop cables meet individually jacketed pigtails or multi-fiber riser cables. Typically, more than one trunk or drop cable is routed to the Splice Enclosure, and at different times (due to later additions).

The ability to access the enclosure in order to add cables, without moving/disturbing "active" fibers already installed within, has been no simple task. Most Splice Enclosures used today are wall-mounted and either top or bottom-fed with cables. Most have pre-punched holes where fiber cables must be "threaded" through (Figure 4A) - a difficult and time-consuming task. A new Splice Enclosure recently introduced by The Siemon Company incorporates a patent-pending slide-in cable entry, providing total accessibility for initial cables, and subsequent additions (Figure 4B).

Figures 4A - Most Splice Enclosures require “threading” of cables

Figures 4A - Most Splice Enclosures require “threading” of cables

|  Figure 4B - The Siemon Company’s new Splice Enclosure has slide-in cable entry for easy cable additions

Figure 4B - The Siemon Company’s new Splice Enclosure has slide-in cable entry for easy cable additions

|

With the slide-in cable entry feature, "threading" of cables is eliminated and previously installed "active" fiber cables need not be moved out of the way to access the cable entry for additions. Further accessibility is provided by the dual storage compartments (Figure 5A) versus the usual one-compartment storage area typical of most splice enclosures (Figure 5B).

Figure 5A - Two, cable slack storage areas instead of one, makes additions easy and fiber cables accessible

Figure 5A - Two, cable slack storage areas instead of one, makes additions easy and fiber cables accessible

|  Figure 5B - One-compartment storage area is typical of most splice enclosures

Figure 5B - One-compartment storage area is typical of most splice enclosures

|

"B" is for Bend Radius Control

In the nineties, it appears that the market also woke up to the fact that bend radius control really is paramount to safe and reliable transmission of information. With the use of Dense Wavelength Division Multiplexing (DWDM), depressed clad fibers, and operation in the 1550nm ranges, fiber cable macrobends become less and less tolerable. Interrupted service from a bent or kinked fiber can now cost thousands of dollars in lost revenues.

The first industry move in the bend radius control quest was to angle the connectors mounted within an enclosure towards the sides. We found that this angling design did provide a bend radius over 2 in., but it also created some accessibility problems:

1. The patchcord cables exiting to the sides draped over the neighboring connections, making access to the adapter bezels difficult.

2. The connectors mounted at the corners of the enclosure (closest to the side walls), both front and back, were also difficult to access because of the angled design (see Figure 5C).

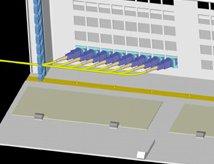

Instead of angling adapters towards the side, The Siemon Company chose to exit patchcord cables straight out of the enclosure, but Siemon also recessed the adapter panel to ensure a bend radius of >2 inches (figures 5D and 5E).

Figure 5C - Angled design - patchcords drape over neighboring connectors making access difficult

Figure 5C - Angled design - patchcords drape over neighboring connectors making access difficult

| |

Figure 5D - (RB Series)

Figure 5D - (RB Series)

|  Figure 5E - (RPA Series) - Both Figure 5D and 5E show that straight-out patchcord cable routing and a recessed adapter panel assure >2 in. bend radius, providing accessibility to connectors

Figure 5E - (RPA Series) - Both Figure 5D and 5E show that straight-out patchcord cable routing and a recessed adapter panel assure >2 in. bend radius, providing accessibility to connectors

|

This design actually improves accessibility as follows:

1. The patchcord cables exiting straight out of the enclosure provide space between the rows to properly access the adapter bezels without disturbing adjacent fibers!

2. The connectors mounted at the corners of the enclosure, both front and back, are easy to access.

How about the protection of the fiber cable as it exits and is routed outside the enclosure? Some plastic cable retainers provide absolutely no bend radius control when cables are pulled, even ever so slightly. And some bend radius protectors available today provide merely a 3/8 in. bend radius – far short of the 1.5 in. minimum bend radius specified by Bellcore (Figure 6A).

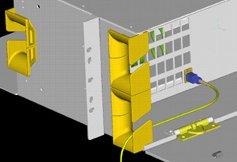

The patent-pending Bend Radius Guide (BRG) provided by The Siemon Company with their new LightWays™ Fiber Optic Enclosures, provides ample bend radius protection for patchcords exiting out of the enclosure, even when cables are pulled taut within the vertical troughs (Figure 6B).

Figure 6A - Some bend radius protectors provide minimal relief to cables exiting the enclosure

Figure 6A - Some bend radius protectors provide minimal relief to cables exiting the enclosure

|

Figure 6B - The Siemon Company’s new BRG provides ample bend radius protection for fiber cables exiting out of the enclosure

Figure 6B - The Siemon Company’s new BRG provides ample bend radius protection for fiber cables exiting out of the enclosure

|

Figure 7 - Compact yet accessible — The Siemon Company’s new staggered Quick-Packs™ incorporate integrated latches for snap-in installation and one finger removal Figure 7 - Compact yet accessible — The Siemon Company’s new staggered Quick-Packs™ incorporate integrated latches for snap-in installation and one finger removal

|

"C" is for Compact Design

There is a definite trade-off between density and accessibility. In the early nineties, Telcos and CATV MSOs pushed suppliers to develop high density enclosures, squeezing 144 fibers into a 7 in. high rack space. New designs were developed and some deployed, but the outcome has not been very promising, nor user-friendly. Accessibility was greatly sacrificed with these new dense enclosures. Some designs tried to combine splicing and patching in the same shelf, and some designs utilized moving shelves. Moving shelves provided some accessibility, but unfortunately introduced failure mechanisms - areas where fibers could be cut, kinked, or crushed by the moving shelf. Moving "active" fibers, however, should be a concern, especially with today’s macrobend-sensitive wavelengths. Most installers and end-users have disbanded the high-density approach, in favor of lower fiber count enclosures which ensure more accessible designs. Nevertheless, The Siemon Company has succeeded in designing a high-density enclosure that is compact yet accessible.

The Siemon Company’s WP series wall mount patch and splice enclosure utilizes the same patented Quick-Pack™ adapter plate used in new rack mount LightWays™ Enclosures, but arranged in a "staggered" position. (Figure 7). This "staggering" of the Quick-Packs™ enables a smaller, more compact size ( 12.25 in. height x 16 in. width x 3.25 in. depth), without sacrificing accessibility.

Conclusion

Select a Fiber Management System that follows the ABCs of proper fiber management. A feature-rich enclosure may cost a bit more than the "bare bones" box, but it will save you a hundred-fold in the long run considering the revenue loss from an interrupted transmission.

Biography

Lou Maiolo is President of Maiolo Associates, a Market Research Company. Based in Long Island New York. He has over 20 years experience in Fiber Optics Passive System Design and Deployment.

Rev. A 1/00

| <== попередня сторінка | | | наступна сторінка ==> |

| Small Form Factor (SFF) Fiber Connectors | | | De-Mystifying Category 5, 5e, 6, and 7 Performance Specifications |

|

Не знайшли потрібну інформацію? Скористайтесь пошуком google: |

© studopedia.com.ua При використанні або копіюванні матеріалів пряме посилання на сайт обов'язкове. |