РЕЗОЛЮЦІЯ: Громадського обговорення навчальної програми статевого виховання

ЧОМУ ФОНД ОЛЕНИ ПІНЧУК І МОЗ УКРАЇНИ ПРОПАГУЮТЬ "СЕКСУАЛЬНІ УРОКИ"

ЕКЗИСТЕНЦІЙНО-ПСИХОЛОГІЧНІ ОСНОВИ ПОРУШЕННЯ СТАТЕВОЇ ІДЕНТИЧНОСТІ ПІДЛІТКІВ

Батьківський, громадянський рух в Україні закликає МОН зупинити тотальну сексуалізацію дітей і підлітків

Відкрите звернення Міністру освіти й науки України - Гриневич Лілії Михайлівні

Представництво українського жіноцтва в ООН: низький рівень культури спілкування в соціальних мережах

Гендерна антидискримінаційна експертиза може зробити нас моральними рабами

ЛІВИЙ МАРКСИЗМ У НОВИХ ПІДРУЧНИКАХ ДЛЯ ШКОЛЯРІВ

ВІДКРИТА ЗАЯВА на підтримку позиції Ганни Турчинової та права кожної людини на свободу думки, світогляду та вираження поглядів

- Гідрологія і Гідрометрія

- Господарське право

- Економіка будівництва

- Економіка природокористування

- Економічна теорія

- Земельне право

- Історія України

- Кримінально виконавче право

- Медична радіологія

- Методи аналізу

- Міжнародне приватне право

- Міжнародний маркетинг

- Основи екології

- Предмет Політологія

- Соціальне страхування

- Технічні засоби організації дорожнього руху

- Товарознавство продовольчих товарів

Тлумачний словник

Авто

Автоматизація

Архітектура

Астрономія

Аудит

Біологія

Будівництво

Бухгалтерія

Винахідництво

Виробництво

Військова справа

Генетика

Географія

Геологія

Господарство

Держава

Дім

Екологія

Економетрика

Економіка

Електроніка

Журналістика та ЗМІ

Зв'язок

Іноземні мови

Інформатика

Історія

Комп'ютери

Креслення

Кулінарія

Культура

Лексикологія

Література

Логіка

Маркетинг

Математика

Машинобудування

Медицина

Менеджмент

Метали і Зварювання

Механіка

Мистецтво

Музика

Населення

Освіта

Охорона безпеки життя

Охорона Праці

Педагогіка

Політика

Право

Програмування

Промисловість

Психологія

Радіо

Регилия

Соціологія

Спорт

Стандартизація

Технології

Торгівля

Туризм

Фізика

Фізіологія

Філософія

Фінанси

Хімія

Юриспунденкция

Knitwear production methods

With industrial progress and improvements in mechatronics technology, the knitting industry has slowly evolved through the ages since its beginnings with William Lee's stocking frame in 1589. From hand flat machines to fully computer-controlled machines, knitting has seen an incredible amount of evolutionary progress, especially in recent years.

As machines improved with evolving technology, so the same did knitting methods; to yield higher productivity, increased efficiency, lower labor and materials costs, and better consistency and quality.

The following is a brief summary of the evolution of the knit production methods, divided into 4 major stages, using production of a cardigan as an example:

CUT & SEW

CUT & SEW

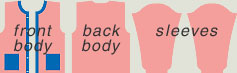

Otherwise known as "panel knitting" or "blanket knitting," cut & sewn production involves knitting an entire panel of knit fabric to accommodate the front body, back body and sleeves. This conventional method requires the patterns for the bodies and sleeves to be cut out from the fabric and sewn together, involving several tedious post-knit processes. To this, separately knitted trimmings and pockets are stitched. With cut & sew, up to 40% of the original fabric may go to waste as cut-loss.

SHAPING

SHAPING

Shaping, or "full-fashioning", allows the front and back bodies and sleeves to be knit according to specific pattern shapes for each piece. Each pattern is shaped using only the amount of yarn necessary to knit that piece and seam allowances, so cut-loss is eliminated. Trimmings and pockets still must be knit separately, and post-knit linking and sewing are still required to complete the cardigan.

INTEGRAL KNITTING

Integral knitting uses shaping technology to knit pattern-shaped pieces as well. It improves upon shaping by "knitting-in" or "integrating" trimmings, pockets and other accessories such as buttonholes to avoid sewing together these items. Great savings can be achieved in post-knit processing, and because trim pieces are knitted-in, quality and consistency is vastly improved.

WHOLEGARMENT

WHOLEGARMENT

WHOLEGARMENT knitwear production, generically known as "complete garment" knitting, is a brand-new method pioneered by Shima Seiki. It is the most advanced form of knitting so far, whereby an entire garment is knit on the machine without any linking or sewing. Incredible cost-savings can be achieved as a result of eliminating all post-knit labor. On-demand knitting capability shrinks production lead-time considerably. With absolutely no material waste, WHOLEGARMENT is considered environmentally friendly. And the garment itself, being seamless, is also very comfortable to wear, and takes advantage of the stretch-quality of knitwear to its fullest. Such qualities unique to WHOLEGARMENT knitwear offer the potential for establishing WHOLEGARMENT as a completely new type of fashion with great added-value.

Typically, a knitted garment consists of separate parts - the front and back body panels and the sleeves, which are sewn together afterward. In sharp contrast, WHOLEGARMENT knitwear is produced in one entire piece, three-dimensionally, directly on the knitting machine. Consequently it requires no post-production labor. A superior alternative to conventional knitting methods, the seamless construction of WHOLEGARMENT realizes substantial benefits unmatched by any other textile product.

Typically, a knitted garment consists of separate parts - the front and back body panels and the sleeves, which are sewn together afterward. In sharp contrast, WHOLEGARMENT knitwear is produced in one entire piece, three-dimensionally, directly on the knitting machine. Consequently it requires no post-production labor. A superior alternative to conventional knitting methods, the seamless construction of WHOLEGARMENT realizes substantial benefits unmatched by any other textile product.

With its truly revolutionary production method, is cause for a major paradigm shift in the modern knitting industry. By producing an entire garment in one complete piece, we no longer have to rely on labor-intensive cutting and sewing processes which cause bottlenecks in the supply-chain flow. With WHOLEGARMENT, great savings in time and cost can be achieved. Cut-loss - the amount of scrap material that is thrown away after cutting out each pattern - is eliminated entirely as well. With WHOLEGARMENT technology, the required number of required garments can be knit at the required time, permitting true "on-demand" quick-response production.

By eliminating sewn seams, WHOLEGARMENT sweaters provide an abundance of benefits for the consumer as well. Bulky and annoying stitches at the shoulders, sides and underarms are gone, offering fit and comfort superior to that of any other textile product. Seams no longer interfere with the natural elasticity of knits, so you can move and stretch more freely. Soft and lightweight, seamless skirts and dresses drape and flow more naturally. And there is nothing to break up the design and silhouette of the garment as originally intended by the designer. The "ideal knitwear", WHOLEGARMENT products raise the essential attributes of knitwear - softness, lightness and resilience - to an entirely new level of sophistication.

WHOLEGARMENT is unique in its ability to knit-in details such as darts and pleats to produce complete 3-D knitwear with a tailored fit. It is the only method, which allows a complete, three-dimensionally shaped and fitted garment to be worn straight off the machine. All production is performed on computerized equipment, and programming is easy using computer graphic design systems. In fact, WHOLEGARMENT goes a step beyond 'computer-to-knit' applications and realizes novel 'computer-to-garment' production.

Читайте також:

- Apparel Production

- C. Evolution of textile production

- CLINICAL METHODS OF PATIENT’S EXAMINATION

- Data Collection Methods for Market Research

- Demo 11: Access Methods (методи доступу)

- Fabrics production and their properties

- I. Text A: «Metals», Text B: «Steel», Text C: «Methods of steel heat treatment»

- III. Manner of noise production and the type of obstruction

- Information technologies in production

- Inspection of Production Facilities and Production Samples

- Kazakhstan to Launch Its Own Infant Food Production

- Knitting methods

| <== попередня сторінка | | | наступна сторінка ==> |

| III Answer the questions about the text | | | III Answer the questions |

|

Не знайшли потрібну інформацію? Скористайтесь пошуком google: |

© studopedia.com.ua При використанні або копіюванні матеріалів пряме посилання на сайт обов'язкове. |